Full Custom IC

APT specializes in ASIC (application specific integrated circuit) development and design services; by integrating global professional technology and dedicated service, we will bring our customers:

Unit cost minimizationMaximize product value

Maximize product performance

Product efficiency optimization

Minimize product volume

Improve product reliability

Improve product reliability

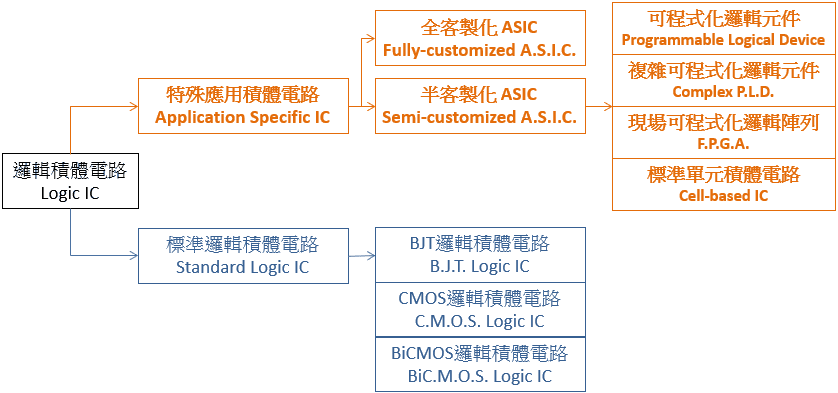

Digital integrated circuits can be classified into Standard Logic IC and Application Specific IC.

【圖一】

Fig1- Taking digital IC as an example, according to product characteristics, it can be roughly divided into standard products (SLIC, widely used IC) and special products (ASIC, special application IC). Among them, ASIC will be further divided into Fully-customized and Semi-customized

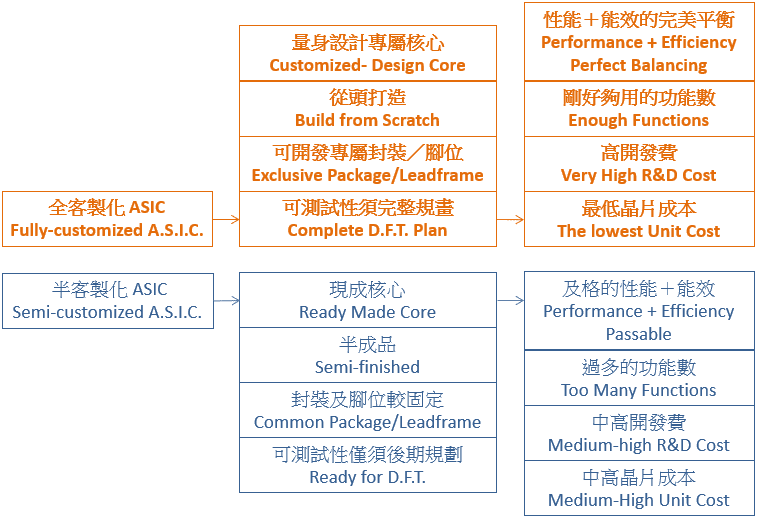

【圖二】

Because the fully customized IC is tailor-made, the development time is long, the development cost of logic design, layout design and photomask is high, and it is CP (wafer test) for mass production testing of wafers and ICs that can be produced smoothly. ), FT (package test) and other test design also need to build a complete platform and program from scratch. If the previous development stage was to be fast and not cautious enough, the development period may be longer due to a revision, so choosing a partner developer is the key to shortening the development period.

Although full customization has high development costs and long development periods, it is also tailored for all needs. The performance and efficiency of the chip will be optimized towards perfection (the standby circuit that is not needed is depleted. Almost non-existent), the number of chip functions will be just right and sufficient (compact and no cumbersome), and the right number of functions means that the circuits that are not needed are minimized, which creates a fully customized IC. Big advantage-minimum unit cost.

The semi-customization is based on the IC design company’s off-the-shelf chip core (chip core), eliminating many early and mid-term logic design and physical layout design, and the timeliness is faster, but under the premise of selecting existing cores, There may still be too many functions, so the performance efficiency ratio is better than the standard product, but it is still not as good as the full customization; the medium to slightly higher development cost is matched with the lower unit cost than the standard product. For cases where the volume is not large or the timeliness is relatively short, semi-customized IC is a good countermeasure.

If the difference between the two is still not clear enough, you can regard full customization as open mold casting, and semi-customization as 3D printing. If the volume is small, the cost of mold opening cannot be amortized, and 3D printing is relatively economical; But when the quantity is large, the opener will benefit from the extremely low unit price. Or you can regard full customization as open-plate printing, semi-customization as printer printing, and standard products as entrusted store photocopying; photocopying is pure copying, which can only be drawn on paper afterwards The cost of a single sheet printed by a laser printer is lower than that of outsourced photocopying, and can be edited in advance, but the cost of the printer, ink or toner must be paid first; as for the fully customized printing , Not only can it be edited in advance, it can be printed with more choices of paper shape, material, weight and thickness, and the types of inks that can be picked are diversified (deinking, durability, water resistance, and fullness of color), and the unit cost is extremely low. The disadvantage is that you must first invest in the cost development version.......